A linear ball slide, often called a linear slide bearing or simply a linear ball bearing slide, is an essential part of many sorts of manufacturing. When it comes to making products, it’s crucial for improving accuracy, productivity, and overall performance. What follows is an examination of the Linear Ball Slide’s function in production:

Motion That Is Both Smooth And Precise

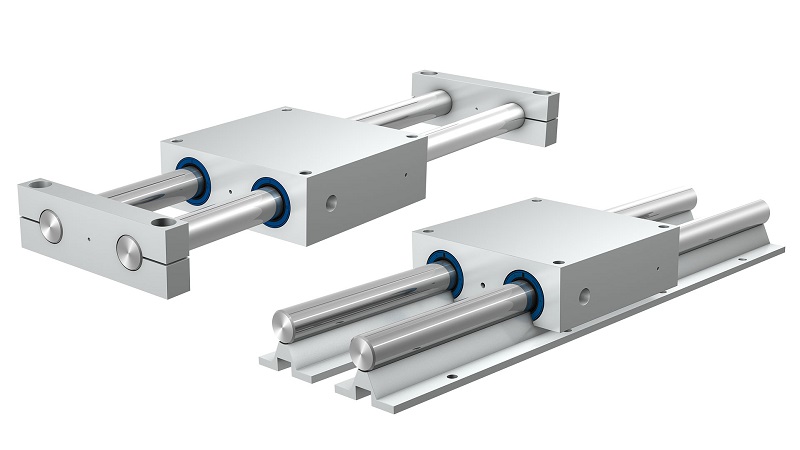

Linear ball slides are able to move smoothly and precisely because they use ball bearings. When precise and regulated motion is essential in production, this is of the utmost importance. The Ball Slide is a crucial component of robotic systems, automated assembly lines, and CNC machines. Its design minimizes friction, which in turn reduces wear and tear and improves overall precision.

Decreased Wear And Friction

When compared to more conventional sliding mechanisms, the Linear Ball Slide’s ball bearings produce rolling contact that drastically decreases friction. Less friction means less wear and tear on components and a more efficient production process overall. Consequently, the Linear Slide helps machines last longer and work more reliably.

Able To Handle Heavy Loads

The smooth operation and heavy load capacity of linear ball slides make them ideal for industrial applications. When working with bulky or heavy components or materials, this is a lifesaver in the manufacturing sector. One major benefit in many industrial uses is the ability to withstand heavy weights with little loss of accuracy.

Reproducible Preciseness

Manufacturing relies heavily on precision, particularly in processes like machining, assembly, and inspection. Tools, components, or workpieces can be moved with repeatable accuracy with the Ball Slide. In order to keep the production process’s quality consistent, this is crucial.

Design Versatility

Linear ball slides are available in a wide variety of styles and configurations, expanding their potential uses. They are versatile and can be used with a wide range of gear and equipment to meet the demands of any given production process. The Ball Slide offers versatile form and usefulness, whether it’s in a horizontal or vertical posture.

Automated Process Improvements

The use of linear ball slides improves the dependability and efficiency of robotic systems in automated industrial operations. Activities including material handling, assembly, and pick-and-place rely on their smooth and accurate action. Energy efficiency in automated systems is enhanced by the reduced friction, which further decreases the power required for movement.

Advantages In Upkeep

Linear ball slides require less maintenance due to the reduced wear and friction they provide. This is especially helpful in industrial environments where maintenance downtime can lead to significant financial losses. Linear ball slides are a useful piece of equipment since they last a long time and don’t break down.

All things considered, the Linear Slide is an essential part of contemporary production that helps with accuracy, productivity, and dependability. The fundamental element in many industrial applications, it facilitates smooth linear motion, handles large loads, and offers repeatable accuracy, thus enhancing the overall quality and productivity of the manufacturing process.